Everything is now out of the panel. Figured out how to get all the controls out of the panel and despite being aware of the ball bearing in the carb heat control, still managed to lose it. Oh well!

The suction system is removed and a secondary static line that wandered up the A-post and connected the altimeter only has been removed (and retained in case it turns out to be needed.)

I’m starting the CAD work for the new panel and the wiring diagram(s). Away all weekend and next week on familty vacation, bringing laptop to continue research and drawings.

Everything to date has been tearing stuff out for inspection and replacement. All necessary and interesting but I hit a snag with the last few controls on the panel so I decided to work on some cosmetics.

The piano keys are a trademark feature of the 120/140/170 family. The 6 switches protrude through the panel and some designer went a bit art deco with them. I’m keeping them (of course) so they had to be smartened up. This restored Cessna 140 has them aong the bottom of this photo.

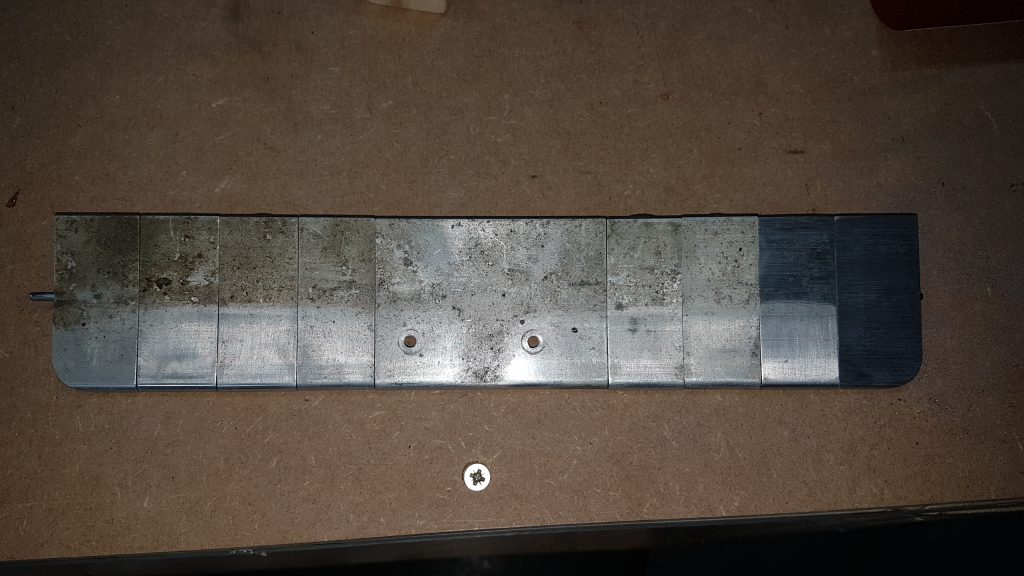

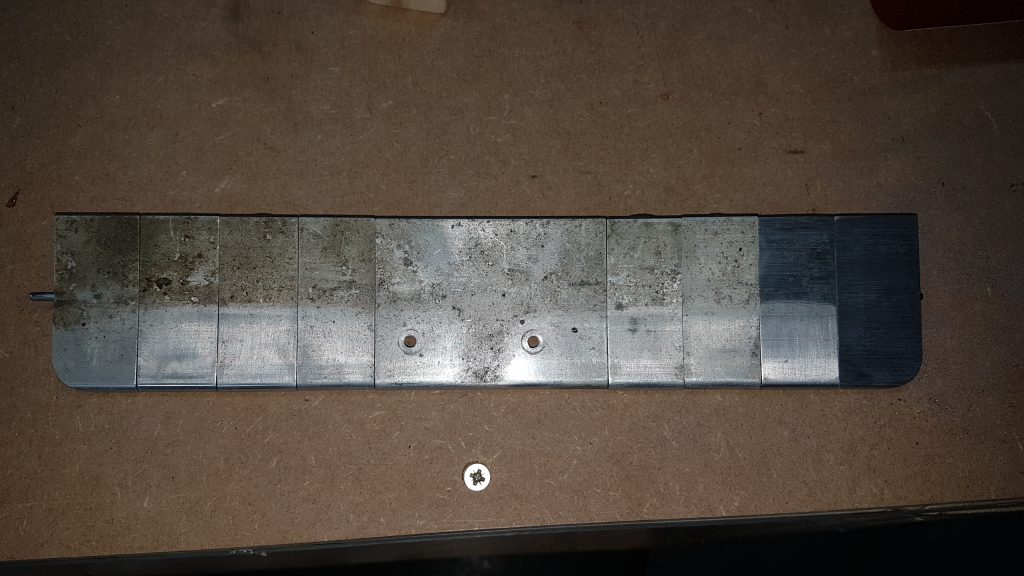

Removed last weekend, they looked like this (except where I had started cleaning:

The switches behind them were all different and mostly trashed. One died during extraction.

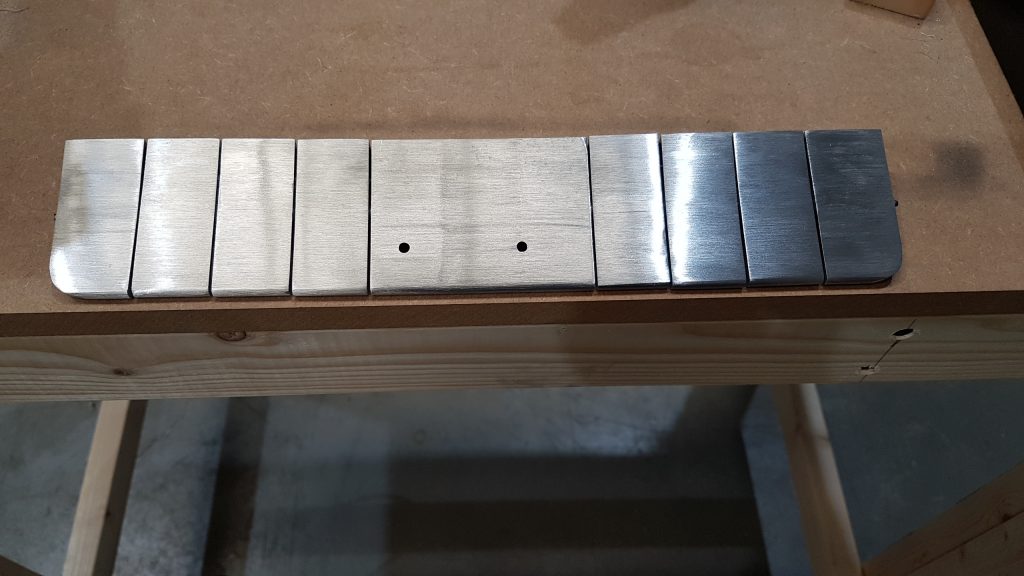

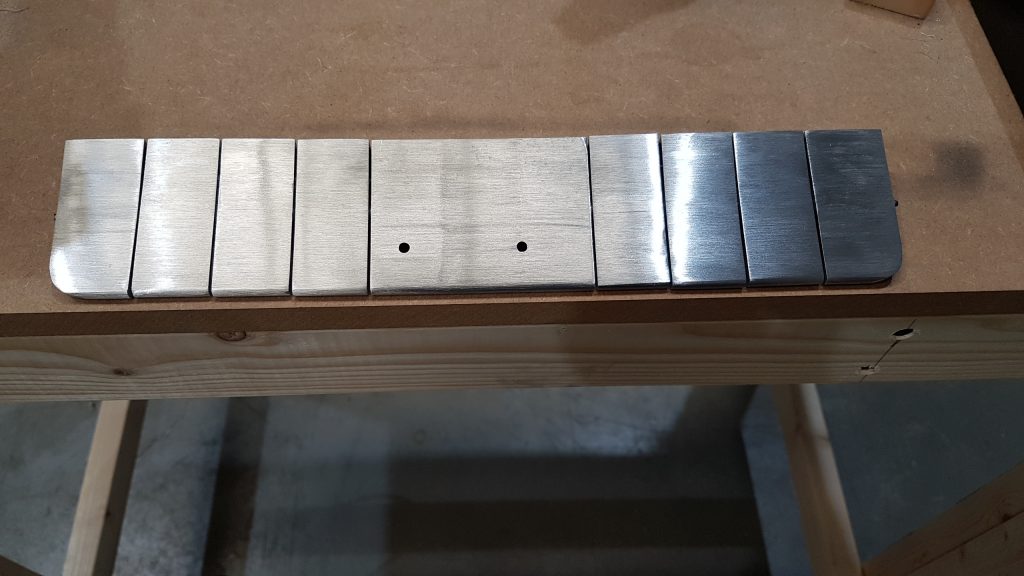

Now they look like this:

The brushed look is intentional (not original) there was too much pitting to just clean and polish them up. Several hours with grinder and polisher and they look and feel much nicer. Not sure why someone drilled holes in the centre piece; and couldn’t get them symmetrical.

The last 2 screws to remove the switch and breaker assembly took 4 hours to get out. Someone had installed a plastic overlay and it was necessary to disconnect all the controls (carb heat, throttle, etc. to get it loose and access the screws). All that is coming out anyway so nothing lost.

Ella: 2 hours scraping draft excluder, cleaning and 2 more turning spanners and passing tools and equipment. Engineer in the making?!

Continued removing interior and panel. Started chopping out the rats nest “harness”. The wiring clearly evolved over time as new systems were added and not all of the vestigial wiring from previous ones was removed. There looked to be at least 5 separate ages of wiring in there and much of the insulation was past its “best before”.

As the aircraft will be VFR day only all the IFR stuff will not be replaced.

Removed seats, carpets, some interior panels, opened all inspection plates and removed shock mounted instrument cluster.

Found half a pound of loose screws, bolts, etc. down the back under the floor where they had obviously migrated after being dropped. Makes one wonder how hard they looked on the last annual!

After being delayed by Irish Customs, which ended up costing an extra EUR1,000; which I really appreciated; N4180V has arrived in Dublin. Her export deregistration paperwork is on its way to the FAA and she will never fly with that tail number again. Having looked her over for only about an hour, I am sorely tempted not to uncover the wings. They look as though they were done not that long ago and there is minimal damage to the ceconite.

We had thought to change up the paint scheme, but after looking through the TIC170A 170 book it appears that this is the original paint scheme (although definitely not the original paint.) I’m now inclined to keep it and while the pattern of the interior fabric was described as “something straight out of Mad Men”, that makes it exactly appropriate to her age.

Next steps are:

- lots of reading of logs, STCs etc. that came with her

- Cleaning everything

- Beginning the strip out of the interior

- Making a list of what to fix, remove, replace, etc.

Happy news: 2 of the 3 mods I was planning: 4-point seat belt harness, and landing light replacement, have already been done. Spin-on oil filter was done on her previous O-300 but I don’t know yet if the replacement engine has it. If not, that will definitely be added probably using the STC that’s already in her log book.

Project hours allocated to completing the shipping drama, continuing research, getting her unloaded and unpacked.

Organizing the shipping ended up being the most stressful part of this so far; largely because the shipping agent was not good. Hopefully things will go smoother when the container arrives.

I have joined The International Cessna 170 Association (TIC170A http://www.cessna170.org/). They have a wealth of information, STCs and all kinds of excellent 170 history along with active forums where I expect to ask many questions during this project.

I found a light industrial unit with office space and a small warehouse/workshop area, which I need for work. Unfortunately the one that is ready now is already gone and it will be August before another is available.

Time spent just organizing things has been in bits and pieces but added up to another 5 hours!

Problem is she’s still in Huntsville, TX and I’m not! Shipping her to Ireland is theoretically not that difficult to arrange, but …

A local A&P took a load of photos for me and he’s all set to pack the parts into a container. The shipping agent has gone silent and not confirmed the container will be there when it’s supposed to be.

I found a prop in PA, which I bought and is being shipped by FedEx to TX in time to go in the container.

ILAS project book has been requested and should know more about that in the coming weeks. The engine will go out for rebuild on the yellow-tagged crankshaft (coming in the box).

Paperwork for the transfer has been completed and is being snail-mailed separately. Once I have that she’ll be de-registered with the FAA and will cease to be N4180V. Eventually she will go on the EI- register.

Now I need to find somewhere to work on her. Once she gets here there will be a full assessment of the work required and a project plan.

She’s in Texas, had a ground loop so wing is injured. There may be more drama involved as she’s an aircraft still on the N register rather than a kit. TBD!

Hours of research have already been sucked up by this!

This is where the description of the work done will go. For this one the work was several hours of figuring out how to use pods.io to make this WordPress site use a custom post type for Kit Log Entries. I will add a custom widget to show a summary of hours spent on each section of the aircraft. I have added a custom taxonomy to differentiate the aircraft sections. The objective is two-fold: to publicly shame me into keeping up the work rate and as a builder’s log to satisfy/facilitate the inspector-type people!

The Cruzer-STOL is/was/may some day become (my proposed) mashup of the two Zenith CH 750 models: Cruzer and STOL. I’m planning to build the Cruzer kit with VGs added to the leading edge of the wings to reduce stall speed and the wheel pants deleted. In fact the undercarriage will likely be the big wheeled STOL version. I’m hoping this will give more STOL and rough field capability while maintaining a lot of the cruise speed improvements of the Cruzer; a compromise of course.